MARKETS

Metval is the trusted partner for those seeking reliable and competitive thermal spraying solutions. Specializing in thermal spray coatings for the automotive, valves, mechanical textiles, pumps, and wire drawing sectors, we stand out for the repeatability and competitiveness of our processes.

RELIABLE AND COMPETITIVE THERMAL SPRAY COATING SOLUTIONS

At Metval, we employ coating technologies such as wire metallization, plasma spraying, HVOF, and electric arc to create coatings that meet the specific needs of our customers.

Key Applications

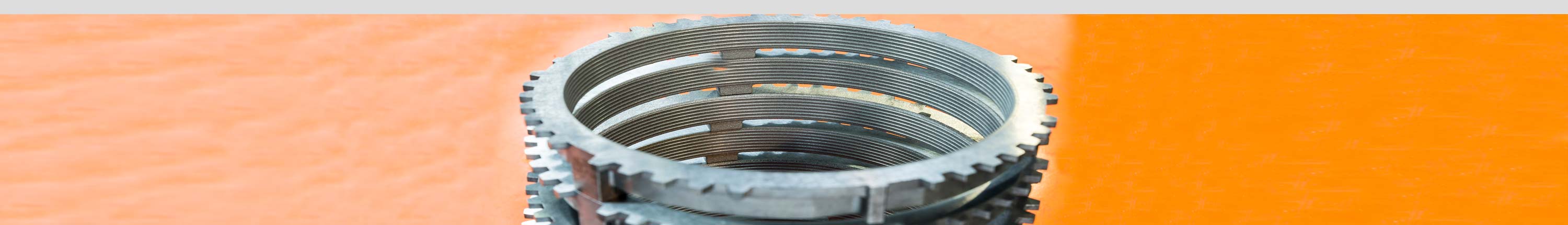

- Automotive:

- Molybdenum coating on synchronizer rings, gears, pins, and differential bushings.

- Molybdenum or bronze coating on gearbox forks.

- Ball Valves:

- Metal-to-metal seals with tungsten carbide (TCC), chromium carbide (CCC), and stellite.

- Mechanical Textiles:

- Ceramic coatings (plasma-sprayed with chromium oxide and alumina-titania) on cylinders, feeding rollers, wire guides, and pulleys.

- Pumps:

- HVOF coatings or ceramic coatings on bushings, pistons, and rings.

- Wire Drawing:

- Plasma-sprayed ceramic coatings and HVOF coatings on pulleys, rollers, drawing rings, and drawing cones.

- Welding:

- Plasma-sprayed ceramic coatings for electrical insulation.

Thermal spray coatings are also used for other purposes:

- corrosion resistance;

- thermal barrier;

- dimensional restoration.

Integrated Processes and Quality Finishing

In addition to our expertise in thermal spraying, Metval offers in-house mechanical processes and surface finishes, including grinding, polishing, and lapping of coatings. This integrated approach ensures maximum quality and control of timelines at every stage of the process.

Certifications and Quality Control

Metval has been UNI EN ISO 9001 certified since March 2010. Our in-house laboratory performs micrographic examinations, checks roughness, hardness, and bend tests to ensure compliance with the required quality standards.